DBCE Mechanical Department conducts Audit course in Maintenance Engineering

The audit course in “Maintenance Engineering” conducted by the Mechanical Engineering Department for third-year students of our college in the 6th semester provides them with a comprehensive understanding of principles and practices in the context of maintenance-related activities. This course aims to equip students with the knowledge and skills necessary to effectively evaluate and improve maintenance processes within an industrial setting. Five technical sessions were conducted throughout the semester by speakers from industry and academia.

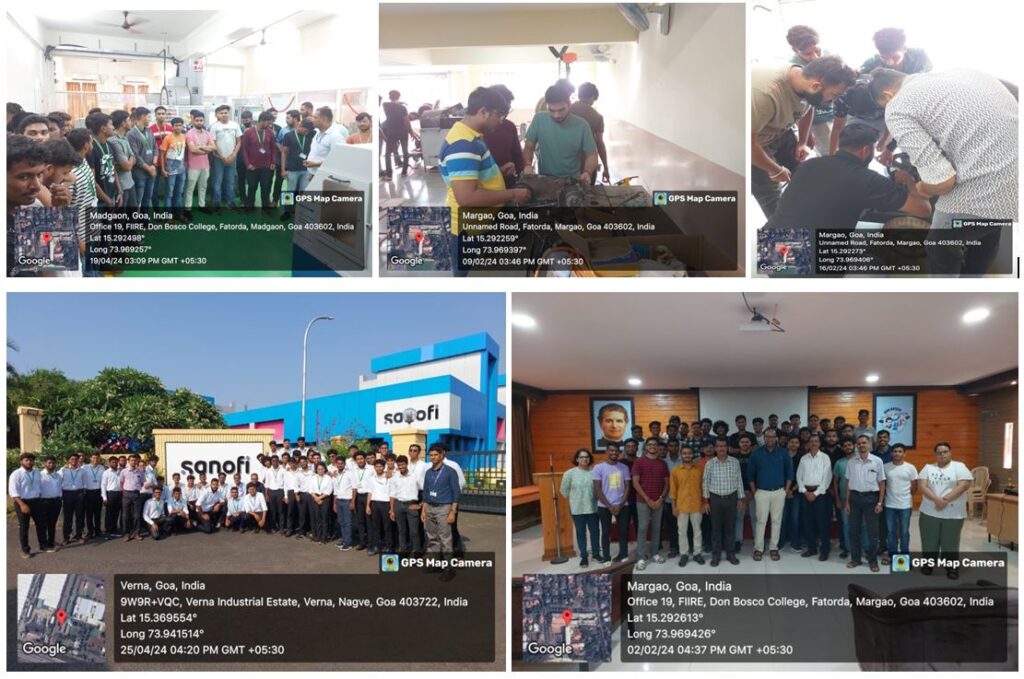

Session 1: Technical Talk on Maintenance of HVAC Equipment

The session was held on 2nd February 2024 and the resource speaker was Mr. Prakash Naik, Past President, ISHRAE Goa Chapter and retired officer from Goa Shipyard Ltd. Mr. Naik provided insight on the need for maintenance and various techniques; namely, Predictive, Preventive & Corrective techniques in maintenance engineering. He highlighted the importance of proper maintenance of HVAC systems as it is crucial for ensuring optimal performance, energy efficiency, and a comfortable indoor environment. He explained the various maintenance-related tasks like filter replacement; coil cleaning, Inspection of refrigerant levels, testing controls and thermostats, etc. He also explained briefly the various tools used in HVAC systems to carry out the maintenance activity.

Session 2 and 3: Practical sessions on dismantling and assembling different components

The sessions were conducted on 9th Feb and 16th Feb 2024 respectively where the students were given the task of dismantling and assembling an air compressor, manual press machine, transformer coil winding machine, and a 2-stroke engine. The purpose of this activity was to gain practical experience and understanding of the working of the machines, gather the necessary tools and equipment for dismantling the component systematically, examine each part during the dismantling process, and reassemble the components by verifying the correct alignment and positioning of each component ensuring each part is fitted correctly and according to specifications.

Session 4: Technical Session on ‘Introduction to CNC Machining’

The session was held on 19th April 2024 at the CNC Center of the college, and was aimed to provide attendees with practical insight into the world of CNC machines and their working. The session was delivered by Prof. Sachin Turi, Prof. Gaurish Samant, and Prof. Aniket Naik, Assistant Professors at the Department of Mechanical Engineering. The session began with an insightful presentation detailing the evolution and significance of CNC technology in various industries. Students were introduced to the intricate components of CNC machines, tool selection, tool path planning, etc. They got first-hand experience with how CNC machines are programmed to execute precise machining tasks and had the opportunity to engage in hands-on activities, where they learned how to set up tools, load materials, and initiate machining operations on a CNC machine.

Session 5: Field Visit to Sanofi Goa Development Center

The visit was organized on 25th April 2024 by Mr. Prasad Adpaikar, Manager of Engineering & Operations. The visit began with a presentation by Mr. Prasad Adpaikar, which covered the overview of Sanofi, various machines, utilities in the plant, various maintenance practices followed for the various utilities, and most importantly the role of engineers in pharmaceutical industries. A short video of the Sanofi R&D Goa development centre was also shown to the students. The students were then taken to the various auxiliary units, which helped them explore the powerhouse substation, boiler & chiller section, air handling units, compressor, diesel generators, etc. Students visited the 1800KW solar plant, where they were shown the monitoring system, which tracks the panel’s performance, energy produced, and carbon emissions saved. The panels are capable of generating enough energy to power the entire facility on sunny days.

All the sessions were coordinated and organized by the coordinators, Asst. Prof.Swapnil Ramani and Asst. Prof. Sharad Shanbhag. The sessions were also attended by the staff of the Mechanical Department.

Visit Today : 602

Visit Today : 602