Audit Course in Maintenance Engineering

The audit course in maintenance engineering conducted by the Mechanical Engineering Department for TE Mechanical (6th sem) Engineering students at Don Bosco College of Engineering provides students with a comprehensive understanding of principles and practices in the context of maintenance activities. This course aims to equip students with the knowledge and skills necessary to effectively evaluate and improve maintenance processes within an industrial setting. Five audit course sessions were conducted throughout the semester by inviting speakers from industry and academia. The details of the sessions are as follows.

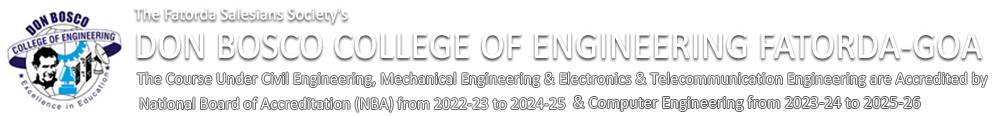

Session 1: Technical Talk on Maintenance in Process Industry

The session was conducted by Mr. Gerard D’Mello, Retired Chief Manager – Projects at Zuari Agro Chemicals Ltd. and Past Chairman of the Institution of Engineers (India), Goa State Centre. He delivered an insightful talk on various types of maintenance, highlighting their respective advantages and disadvantages. He emphasized the critical role of maintenance in the process industry, discussed best practices, explored different maintenance strategies adopted in process industries, and shed light on the common challenges faced in implementing effective maintenance systems.

Session 2: Basic concepts of HVAC and its application in Industries

The resource person, Mr. Deepak Rodrigues, Associate Director and Head of Utility Operations at Cipla Ltd., delivered a talk on “HVAC Systems in Pharmaceutical Industries.” He covered key topics including psychrometrics, cooling load calculations, cleanroom environments, and ducting systems. His session provided students with valuable practical insights into the challenges and industry practices associated with HVAC systems in the pharmaceutical sector.

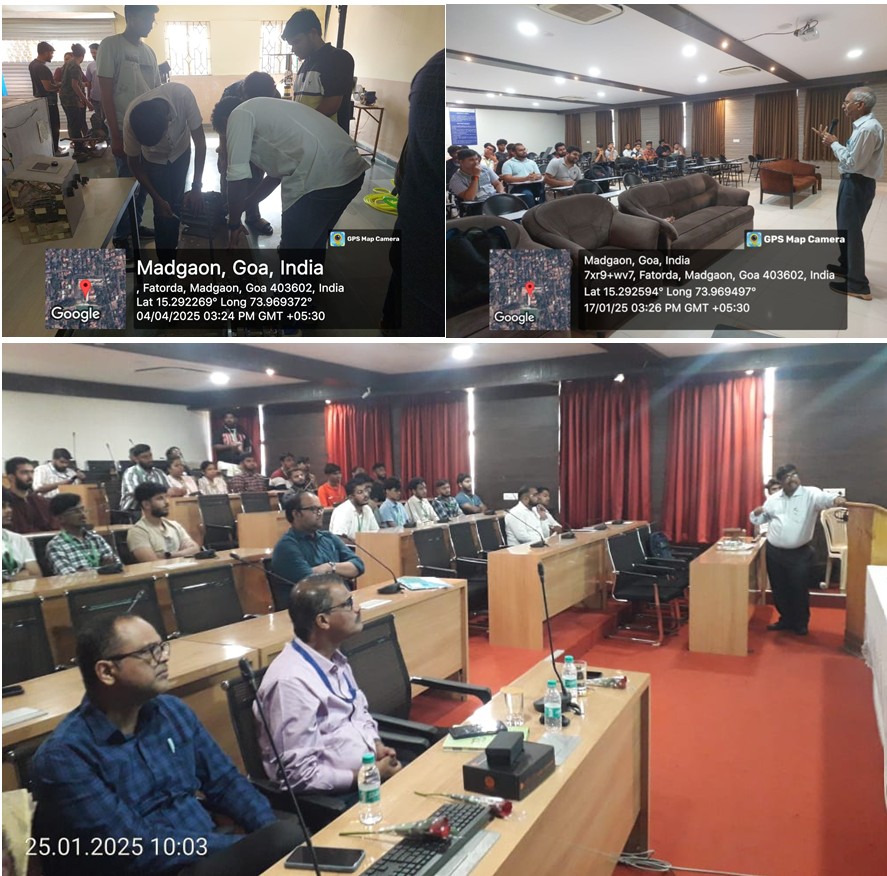

Session 3 and 4: Practical sessions on dismantling and assembling different components

For the practical session, students were provided with components such as an air compressor, manual press machine, transformer coil winding machine, and a 2-stroke engine. They were assigned the task of dismantling and reassembling the given equipment. The objective of this activity was to help students gain hands-on experience and a deeper understanding of the internal mechanisms of these machines. The exercise involved systematically gathering the necessary tools, carefully disassembling each component, closely examining individual parts, and reassembling the equipment while ensuring proper alignment, positioning, and adherence to specifications.

Session 5: Field Visit to Sanofi Goa Development Center

The industrial visit was coordinated by Mr. Prasad Adpaikar, Manager of Engineering & Operations at Sanofi Health Care Pvt. Ltd. He began the session with a brief presentation, providing an overview of Sanofi, the various machines used, and the maintenance practices implemented for different utilities. Following the presentation, Mr. Prasad and his engineering team guided the students through the R&D unit and several auxiliary sections. They gave a concise explanation of key equipment used in the Formulation and Development Lab, such as the Rapid Mixing Granulator (RMG), Fluidized Bed Processor (FBP), and blenders. The students were also shown the stabilization room, a vital part of the R&D process.

Additionally, the visit included a tour of the powerhouse substation, boiler and chiller sections, air handling units, compressor systems, and diesel generators, giving students a comprehensive view of the facility’s utility infrastructure.

Visit Today : 729

Visit Today : 729